Добродошли у АУТОМОБИЛ

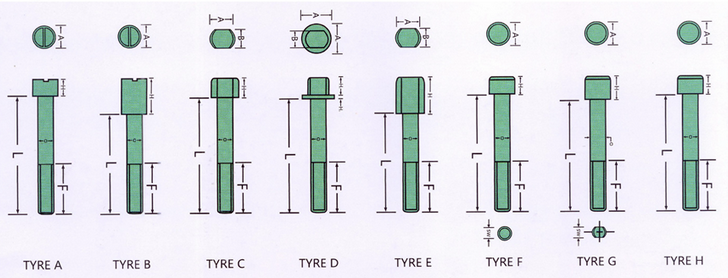

Различити типови централних вијака за приколицу са лиснатим опругама

Детаљ

| Врсте | Тип А, Б, Ц, Д, Е, Ф, Г, Х |

| Материјал | 42CrMon, 35CrMon, 40Cr, 45# |

| Оцена | 12,9; 10,9; 8,8; 6,8 |

| Бренд | Ниссиан, Исузу, Сцанниа, Митсубисхи, Тоиота, Ренаулт, БПВ, Ман, Бенз, Мерцедес |

| Завршна обрада | Боја за печење, црни оксид, поцинкована, фосфат, електрофореза, дакромет |

| Боје | Црна, сива, златна, црвена, сребрна |

| Пакет | Картонска кутија |

| Плаћање | Пореска одобрења, акредитив |

| Време испоруке | 15~25 радних дана |

| Минимална количина залиха | 200 ком |

Апликације

Централни вијци и навртке су врста причвршћивача који има две компоненте - сам вијак, који је обично направљен од челика или друге металне легуре, и навртку, која је обично направљена од пластике или метала. Вијак има главу на једном крају са навојем тако да може да прихвати навртку. Навртка има унутрашњи навој који се заврће на спољашњи навој вијка. Када је навртка потпуно затегнута на вијак, ствара се сигурно држање између два дела. Централни вијци и навртке имају много примена у разним индустријама. У аутомобилским применама за причвршћивање компоненти попут кочница или издувних система; у свакој примени, централни вијци и навртке пружају чврсту везу између два дела, а истовремено им омогућавају да се крећу независно ако је потребно. У склопу лиснате опруге, један од најважнијих делова је централни вијак. У средишту сваког листа налази се рупа. Вијак се провлачи кроз ову рупу у сваком од четири, пет или више листова који чине опругу. Ефективно, централни вијак држи листове заједно и ставља их у контакт са осовином. Глава централног вијка се спаја са осовином, што камиону даје задње вешање у комбинацији са лиснатим опругама. Упркос свом значају, централни вијак је такође један од потенцијално најрањивијих делова лиснате опруге. Да би се осигурало да централни вијак не пукне због савијања листова, потребна је друга компонента која ће чврсто везати листове у облику склопа опруге. У ту сврху, U-вијци повезују лиснате опруге. Са сваке стране централног вијка, U-вијци стежу листове у чврсту опругу. Централни вијак се ослања на U-вијке и обрнуто како би одржао чврсте лиснате опруге са обе стране задње осовине камиона. Сходно томе, ако су U-вијци превише лабави, централни вијак би на крају могао да пукне због притиска савијајућих листова. Да би U-вијци правилно обављали свој посао, потребан је одговарајући обртни момент за њихово причвршћивање. Ово штеди лиснату опругу од проблематичних покрета који би могли оштетити листове, осовину, а посебно централни вијак. На камионима где U-вијци нису довољно причвршћени, оштећења се обично јављају следећим редоследом — прво се средишњи вијак поломи, затим појединачни листови опруге брже попуштају због пукотина изазваних савијањем сваког листа у односу на површину суседног. Уклањање средишњег вијка лиснате опруге може бити тешко или лако, у зависности од врсте хвата којим успете да добијете клин. Иако може бити корисно знати како да уклоните средишњи клин из лиснате опруге, можда ћете сматрати да је најбоље да потпуно замените лиснату опругу.

Референца

Продукција

Паковање и достава

Опрема за контролу квалитета